Opis produktu

Podczas pracy transformatora, nasza spawarka do zgrzewania doczołowego prętów stalowych i drutu wykorzystuje standardowe zasilanie sieciowe do obniżenia napięcia i zwiększenia prądu elektrycznego. To niskie napięcie, wysoki prąd jest przesyłany z elektrody do punktu połączenia dwóch elementów obrabianych. W punkcie połączenia rezystancja obrabianego elementu generuje wysokie temperatury, powodując, że metal osiąga stan stopienia. Ten proces umożliwia precyzyjne spawanie dwóch elementów obrabianych. Jako profesjonalni producenci spawarek do zgrzewania doczołowego prętów stalowych i drutu, utrzymujemy silne możliwości technologiczne produkcji.

Inteligentny system kontroli spawania

Możliwość wyboru źródeł zasilania AC lub MF DC. Kontroler umożliwia przechowywanie różnych modeli spawania dla różnych materiałów i grubości drutu.

Elektroda spawalnicza

Zaprojektowana do tworzenia wielu rowków na elektrodach, umożliwiając jednemu zestawowi elektrod spawanie różnych średnic drutu.

Dostosowane specjalne formy spawalnicze

Przetwarzamy i produkujemy odpowiednie formy zgodnie ze specyficznymi wymaganiami dotyczącymi zgrzewania doczołowego produktu, upraszczając procesy pracy.

Automatyczne ramię załadunku i rozładunku

Nasze spawarki doczołowe mogą być wyposażone w automatyczne ramiona załadunku i rozładunku, umożliwiając integrację z giętarkami 2D/3D w celu w pełni zautomatyzowanych procesów formowania i spawania.

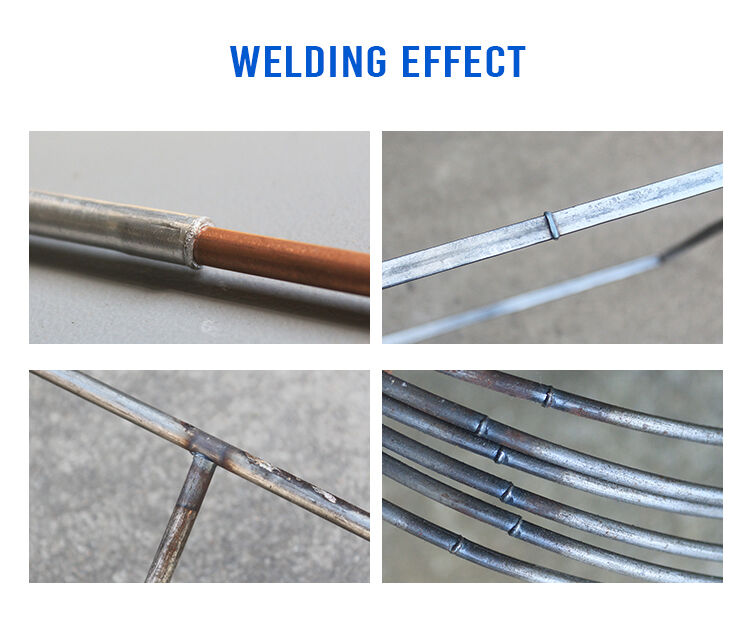

Zastosowanie i próbki

Zapewniamy kompleksowe usługi dostosowane do potrzeb klienta. Nasi inżynierowie omówią Twoje specyficzne wymagania dotyczące spawania i opracują odpowiednie propozycje techniczne w oparciu o Twoje próbki lub rysunki.

Zastosowanie

Nadaje się do spawania czołowego stali węglowej, miedzi, aluminium, stali nierdzewnej, stali stopowej i innych materiałów, w tym drutu, pręta i rury.

Sprzęt do produkcji półek drucianych

Projektujemy kompletne, w pełni automatyczne lub półautomatyczne maszyny do produkcji półek drucianych do lodówek. Dostarczamy szczegółowe rysunki produktów i wymagania dotyczące wydajności, a nasz zespół inżynierów przygotuje spersonalizowane propozycje.

Maszyna do spłaszczania i cięcia drutu

Ta maszyna przetwarza okrągły drut na płaski drut, automatycznie podając okrągły drut i tnąc go na wymagane długości. Zazwyczaj przetwarza cewki drutu 8 mm na płaskie paski drutu 12x3 mm.

Szybka maszyna do prostowania i cięcia drutu

Umożliwia produkcję seryjną drutów o średnicy od 2 mm do 4 mm. Działając z prędkością prawie 5 razy większą niż standardowe maszyny do cięcia drutu, znacznie zwiększa tempo produkcji i redukuje koszty pracy.

Giętarka do ram drucianych

Zgina płaskie lub okrągłe druty w ramki druciane o kształcie kwadratu. Zdolna do gięcia wielu drutów jednocześnie w celu zwiększenia tempa produkcji.

Spawarka doczołowa do ram drucianych

Liczba głowic spawalniczych zależy od szerokości spawania siatki. Różne głowice spawalnicze mogą być zaprogramowane z indywidualnymi programami spawania i prądami.

Maszyna do podwójnego zgrzewania T-Butt do ram drucianych

Spawa poprzeczki półek drucianych do ram drucianych. Konstrukcja z podwójną głowicą zwiększa tempo produkcji dzięki łatwej obsłudze. Projektujemy również automatyczne aplikacje do przemieszczania i spawania.

Maszyna do przycinania krawędzi drutu

Po spawaniu ta maszyna do przycinania odcina krawędzie drutu z ram drucianych, zapewniając czyste i gładkie powierzchnie.

Giętarka do uchwytów drucianych 2D

Zgina uchwyty druciane do drutów o średnicy 2-6 mm. Zdolna do tworzenia różnych kształtów drutu bez konieczności zmiany form.

Giętarka do drutu 3D

Zgina druty w kształty 3D dla drutów o średnicy 2-6 mm lub 3-8 mm. Tworzy złożone kształty drutu 3D bez zmiany form.

Pakowanie i dostawa

Profesjonalny zespół serwisowy

Przez lata Hwashi wykształciło utalentowanych, oddanych i innowacyjnych profesjonalistów. Utrzymujemy zespół ekspertów z bogatym doświadczeniem w inżynierii elektrycznej, projektowaniu mechanicznym i technologii spawania.

Od momentu założenia 22 lata temu, Hwashi Technology obsługuje klientów na całym świecie, uczestniczyło w ponad 100 wystawach i obsłużyło ponad 8000 klientów.

Często zadawane pytania

P1: Jaka jest cena Twojej maszyny?

Nasze maszyny są dostosowane do Twoich wymagań. Aby otrzymać odpowiednią cenę, prosimy o podanie: materiału i grubości Twojego produktu, minimalnego i maksymalnego rozmiaru produktu, pozycji spawania, pożądanego poziomu automatyzacji oraz szczegółowych rysunków produktu w celu uzyskania propozycji technicznych.

P2: Jaki jest okres gwarancji na Twoją maszynę?

Standardowa gwarancja wynosi jeden rok po wysyłce. Okresy przedłużonej gwarancji są dostępne za dodatkową opłatą.

P3: Co się stanie, jeśli moja maszyna zostanie uszkodzona w okresie gwarancji?

Nasi inżynierowie zapewniają zdalną diagnozę problemu. W okresie gwarancji bezpłatnie wymieniamy uszkodzone części. Jeśli problemy nadal występują, wysyłamy inżynierów do Twojej fabryki w celu rozwiązania problemu.

P4: Jaki jest czas dostawy Twojej maszyny?

Standardowe maszyny są zazwyczaj wysyłane w ciągu siedmiu dni po dokonaniu płatności. Maszyny dostosowane do potrzeb klienta wymagają 30-90 dni na ukończenie.

P5: Czy możemy wysłać próbki do testów spawalniczych?

Tak. Przeprowadzamy testy spawalnicze i dostarczamy zdjęcia/filmy. Możemy zwrócić przetestowane próbki w celu weryfikacji jakości.

P6: Czy możesz dostarczyć rysunki maszyn i propozycje techniczne?

Tak. Po otrzymaniu wymagań i rysunków, dostarczamy propozycje techniczne z rysunkami koncepcyjnymi. Szczegółowe rysunki konstrukcyjne są dostarczane do potwierdzenia przed produkcją.

P7: Jakie są Twoje warunki płatności?

Akceptujemy T/T, L/C, Western Union i Alibaba Trade Assurance. Polecamy Alibaba Trade Assurance dla ochrony kupującego.

P8: Jak instalujemy maszynę?

Proste maszyny zawierają instrukcje w języku angielskim, filmy instruktażowe i szkolenia online. Złożone maszyny obejmują usługi instalacji inżynierskiej za dodatkową opłatą.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!